Boom Lift Tires vs. Tracks: Which is Right for You?

When it’s time for your next boom lift — whether you’re renting or buying — you may be inclined to quickly select the most appropriate wheeled model. But in recent years you may have noticed that more and more tracked models are showing up on a range of worksites. That’s because there’s growing awareness that tracks can offer performance advantages over wheels in certain situations.

Continue Reading

8 MEWP Safety Tips for Facility Managers and Workers

Once equipment is in the field, operators must follow the prescribed operating practices outlined in the manufacturer’s operator’s manual to keep the equipment working safely and productively. The best way to reduce risks while operating a boom lift and scissor lift is to know and follow these eight tips.

Continue Reading

Your Electric MEWP Questions Answered

We at Genie have been hearing from contractors and other equipment users — and from rental companies and dealers — with questions about charging, performance, operation and more when it comes to electric boom lifts and electric scissor lifts. With that in mind, here are our responses to some of the most frequently asked questions about electric mobile elevating work platforms.

Continue Reading

5 Ways Quality Principles Can Improve Your Bottom Line

While quality certainly impacts manufacturing and production, all functions and all businesses — not just manufacturing — can benefit from defining and deploying quality management systems throughout their organization.

Continue Reading

Why Your New Genie Machine Has More than 10 Years of Life on It

When you’re shopping for a new piece of aerial equipment or a material handler, you probably have a long list of questions related to machine features, specs and cost. But how often do you inquire about the research and development that went into that product?

Continue Reading

3 Aerial Industry Trends We’ve Identified Midway Through the Year

The halfway point of the year is a good time to check in on what’s been happening in our industry and what’s to come. Here are three trends I’ve seen rise to the top in 2022.

Continue Reading

The Evolution of Customer Experience

How we buy, sell and interact has and is continuing to evolve, and is much different today than it was even a few years ago.

Continue Reading

Celebrating International Women’s Day 2022

In celebration of International Women’s Day, we interviewed two Genie customers who are female leaders in the equipment rental industry.

Continue Reading

Tips for Transporting a Boom Lift

Booms lifts are common equipment on a variety of different jobsites. But before you can start working with a boom, you have to get it to the jobsite. To do this safely and efficiently, there are some important considerations.

Continue Reading

Extreme Height MEWP Applications

Over the past two decades, as jobsite needs have continued to evolve, manufacturers like Genie® have developed boom lifts that can reach higher, lift more, and tackle more extreme applications, providing more and more options for accessing tall, hard-to-reach jobsites.

Continue Reading

How to Tow a Trailer-Mounted Boom

In addition to the ability to reach up, over and out, one of the features that make trailer-mounted booms a popular option for work at height is their ease of transport and mobility.

Continue Reading

Scissor Lift Accessories for Productivity

For scissor and boom lift operators, it’s not just about how high the lift can go or how far it can reach, but also how to the get the job done once they’re at height.

Continue Reading

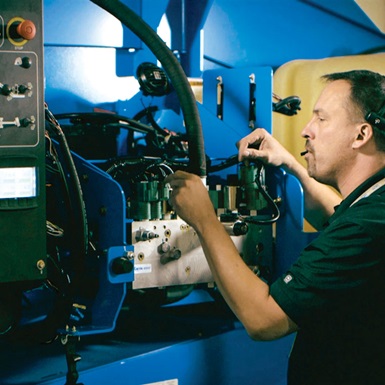

Quality By Design

From the first compressed air material lift in 1966 that started an industry, to the modern machines coming out of our factories today, Genie® has been the leading name in mobile elevating work platforms (MEWPs).

Continue Reading

Load Sense on Scissor Lifts

Genie® GS™ slab scissor lifts are designed to deliver reliability and performance on the jobsite, and for your rental business.

Continue Reading

How to Properly Maintain Your Genie® Telehandler

Genie was excited to introduce the updated Genie® GTH™-1056 telehandler to its line-up earlier this year. But even new equipment needs regular maintenance to ensure that it's running at peak-performance levels.

Continue Reading

Changes to Genie® Booms You Need to Know About

When the new ANSI A92 (United States) standards went into effect, driving alignment with ISO standards globally (including European EN280, Australian AS 1418.10 and Canadian CSA B354 standards), it impacted the way Genie® aerial access equipment is designed, manufactured, maintained and operated globally.

Continue Reading

Choosing the Right Material Lift

Having a diverse equipment fleet to meet the needs of a wide range of professionals is an essential component to help manage the ebb and flow of regular economic cycles.

Continue Reading

Genie Safety Minute: Overhead Obstructions

Genie Safety Minute is intended to facilitate health and safety discussions on the job site.

Continue Reading

The Benefits of Online Training for Aerial Equipment Technicians

Investing a little time in training to gain a lot more later is a basic principle that most far-sighted entrepreneurs agree upon for two simple reasons

Continue Reading

Why Outsourcing Maintenance Can Be the Right Choice for Your Fleet

For equipment owners, a fully and properly maintained mobile elevated work platform (MEWP) can mean reduced downtime, increased utilization, better rental rates and higher residual values. But, performing maintenance to a high standard requires the right knowledge and training.

Continue Reading

Load Calibration for Load Sense

“Load sense” is likely a term you’ve been hearing more of lately. But, what is the primary purpose of load sense, and why does it matter when you’re operating a mobile elevating work platform (MEWP)?

Continue Reading